Welcome to Hollywood Prints, your go-to resource for DTF transfers! If you’re curious about direct to film (DTF) transfers, you’ve come to the right place.

In the world of custom apparel printing, there are multiple printing methods available, each with its advantages and disadvantages. Whether you’re a business owner, a hobbyist, or someone looking to start a custom printing business, understanding the differences between these methods is essential. One of the most innovative printing technologies today is Direct-to-Film (DTF) printing, but how does it stack up against screen printing, sublimation, and heat transfer vinyl (HTV)? In this article, we’ll compare these popular printing techniques to help you determine which one is best for your needs.

Let’s dive into the world of DTF printing together!

Table of Contents

-

What is DTF Printing?

-

How Does DTF Printing Work?

-

DTF vs. Screen Printing

-

Screen Printing Overview

-

Pros of Screen Printing

-

Cons of Screen Printing

-

DTF vs. Screen Printing: Which is Better?

-

-

DTF vs. Sublimation Printing

-

Sublimation Printing Overview

-

Pros of Sublimation

-

Cons of Sublimation

-

DTF vs. Sublimation: Which is Better?

-

-

DTF vs. Heat Transfer Vinyl (HTV)

-

HTV Overview

-

Pros of HTV

-

Cons of HTV

-

DTF vs HTV: Which is Better?

-

-

Cost Comparison: Small vs. Large Orders

-

Start Your DTF Journey Today

What is DTF Printing?

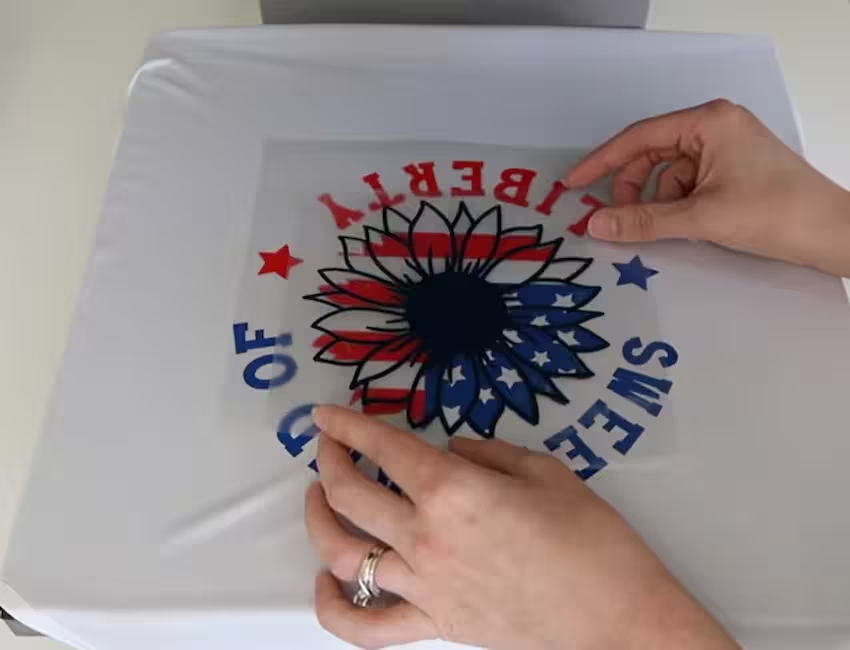

DTF (Direct-to-Film) printing is an innovative garment printing technique that allows you to create high-quality, full-color designs and transfer them onto various fabrics. The process starts by printing your design onto a specialized PET (polyethylene terephthalate) film using a DTF printer and special pigment-based inks. After printing, a layer of hot-melt adhesive powder is applied to the design, which is then cured using heat to activate the adhesive.

Once the print is ready, it can be transferred onto a garment using a heat press, bonding the ink and adhesive to the fabric. Unlike traditional methods like screen printing or sublimation, DTF doesn’t require pretreatment of garments, making it more efficient and versatile. It works exceptionally well on both light and dark fabrics, including cotton, polyester, blends, denim, and even leather.

One of the biggest advantages of DTF printing is its durability when printed correctly as the prints are flexible, stretchable, and resistant to cracking or fading after multiple washes. This makes it an ideal choice for custom t-shirts, hoodies, uniforms, and other apparel, offering businesses and independent printers a cost-effective way to produce high-quality custom garments with minimal setup.

Want to try DTF printing for yourself? Check out our custom DTF transfers for high-quality prints on any fabric.

How Does DTF Printing Work?

-

Design Creation – A digital design is created using graphic design software.

-

Printing – The design is printed onto a PET film using a DTF printer and special water-based inks.

-

Powder Application – A hot-melt adhesive powder is applied to the wet ink.

-

Curing – The powder is cured using a heat press or conveyor dryer.

-

Transfer – The film is pressed onto a garment at high temperature, transferring the design permanently.

Now that we understand DTF printing, let’s compare it with other common printing techniques.

DTF vs. Screen Printing

It’s important to understand the differences between DTF and the other printing types. Now we will discuss the differences between DTF Vs. Screen Printing and go in depth on each to help you decide on which one you’d like to use for your brand or business.

Screen Printing Overview

Before diving in, we need to directly talk about what is screen printing. Learning what screen printing is will help you make a better choice when deciding between the printing types available. Screen printing is one of the oldest and most widely used printing methods, dating back over a thousand years. It involves creating a stencil, or “screen,” made of mesh that is coated with a light-sensitive emulsion. The design is burned into the screen, leaving open areas where ink can pass through. Ink is then pushed through the mesh using a squeegee, transferring the design onto the fabric. Each color in a design requires a separate screen, making multi-color prints more labor-intensive. While screen printing is known for its vibrant, long-lasting colors and soft feel, it requires extensive setup and is best suited for high-volume production runs. Despite the setup costs, it remains a popular choice for bulk orders due to its cost-effectiveness at scale and ability to produce bold, high-opacity prints on a variety of fabric types.

Pros of Screen Printing:

-

Great for bulk orders due to cost efficiency in large runs.

-

Produces vibrant and durable prints with a soft feel.

-

Works well on a variety of fabrics.

Cons of Screen Printing:

-

High setup costs (each color requires a separate screen).

-

Not ideal for small orders or complex, multi-color designs.

-

Limited to mostly flat surfaces (not great for hats, shoes, or other shaped items).

DTF vs. Screen Printing: Which is Better?

Both DTF (Direct-to-Film) printing and screen printing are excellent methods for custom apparel, but they serve different business needs. Choosing the right one depends on order size, design complexity, and budget.

When to Choose DTF Printing:

- Best for Small Orders & On-Demand Printing – No setup fees or screens required, making it ideal for short runs, custom prints, and one-off designs.

- Works on Any Fabric & Any Color – Unlike screen printing, DTF prints cotton, polyester, blends, spandex, and even leather with full-color designs on both light and dark fabrics.

- Highly Detailed, Multi-Color Designs Without Extra Costs – Perfect for photorealistic prints, gradients, and intricate artwork without layering multiple inks.

- Fast Turnaround & Less Labor-Intensive – No drying between layers; once transferred, DTF prints are ready to wear, making it more efficient for small businesses and custom brands.

- Great for Expanding Product Offerings – Since DTF prints can be stored and applied later, businesses can offer heat-pressed designs on demand without maintaining excess inventory.

When to Choose Screen Printing:

- Best for Large Bulk Orders – Once screens are set up, screen printing is cost-effective for high-volume runs (50+ shirts) with simple designs.

- Durable & Long-Lasting – Ink embeds directly into the fabric, making it a top choice for work uniforms, sports teams, and promotional apparel that need to withstand repeated washing.

- Lower Cost Per Unit on Large Orders – While the initial setup is expensive, the per-shirt cost decreases significantly for bulk printing.

- Ideal for Simple, Bold Designs – Works best with solid colors, logos, and text-based graphics, but additional colors increase costs due to multiple screen setups.

- More Traditional Look & Feel – Offers a vintage, hand-crafted aesthetic, which is preferred by many brands for a classic streetwear or retro style.

Which is Better for Your Business?

- For small orders, highly detailed artwork, or printing on various fabrics, DTF is the superior choice because it eliminates setup costs and offers full-color, high-quality prints.

- For large bulk orders with simple designs, screen printing is more cost-effective due to its lower per-unit cost after setup.

Many print shops combine both using screen printing for bulk uniform orders and DTF for smaller, custom jobs which helps maximize efficiency and profitability. Choosing the right method depends on your business model, production capacity, and customer demand.

DTF vs. Sublimation Printing

It’s important to understand the differences between DTF and the other printing types. Now we will discuss the differences between DTF Vs. Sublimation Printing and go in depth on each to help you decide on which type of printing you’d like to use for your brand or business.

Sublimation Printing Overview

Designing for DTF transfers involves using graphic design software such as Adobe Illustrator (AI) and Encapsulated PostScript (EPS) files. These formats ensure high-quality designs that can be accurately reproduced. The design process is crucial as it sets the foundation for the final print’s quality and detail. Using these software tools allows for precision and creativity, ensuring that the design is ready for the printing process.

Pros of Sublimation:

-

Produces vibrant, long-lasting prints that won’t fade, crack, or peel.

-

Works well for full-color, intricate designs.

-

No feel to the print as the ink dyes becomes part of the fabric.

Cons of Sublimation:

-

Only works on light-colored, polyester fabrics or coated surfaces.

-

Can’t be used on cotton or dark fabrics.

-

Requires specialized materials and high temperatures.

DTF vs. Sublimation: Which is Better?

- Sublimation is best for polyester and light-colored fabrics, making it ideal for sportswear, jerseys, and promotional items.

- DTF works on all fabric types (cotton, polyester, blends, and dark fabrics), providing more versatility for apparel businesses.

- Sublimation offers no-feel, permanent prints, but it requires polyester and won’t work on cotton or dark materials.

- DTF allows for high-detail, full-color designs on various textiles without fabric restrictions.

- DTF is better for general apparel businesses, while sublimation is great for niche markets like sportswear and custom hard goods.

For brand owners and business owners, DTF is the smarter choice if you want to print on a variety of materials without being limited to polyester. However, if your business specializes in polyester-based products like athletic wear or mugs, sublimation remains an excellent option. Many print shops benefit from offering both methods to maximize product offerings and revenue potential.

DTF vs. Heat Transfer Vinyl (HTV)

It’s important to understand the differences between DTF and the other printing types. Now we will discuss the differences between DTF Vs. HTV and go in depth on HTV so you can decide on which one you’d like to use for your brand or business.

HTV Overview

The adhesive powder must be applied evenly to ensure proper bonding. Techniques such as shaking and spreading the powder can help achieve an even coat. Ensuring that the powder is evenly distributed across the design is crucial for achieving high-quality results. This step is essential for ensuring that the design adheres properly to the fabric during the transfer process.

Pros of HTV:

-

Works well for simple, single-color designs.

-

Ideal for names, numbers, and small customizations.

-

Affordable entry cost as it only requires a vinyl cutter and heat press.

Cons of HTV:

-

Layering multiple colors is very time-consuming and difficult, even one color designs are time consuming.

-

Less durable than DTF or screen printing as the HTV can crack or peel much faster over time.

-

Limited design capabilities (no gradients or high-detail images) as it’s harder to weed and press.

DTF vs. HTV: Which is Better?

- HTV is best for simple, single-color designs, such as names, numbers, and small customizations.

- DTF excels in full-color, high-detail prints with gradients, fine details, and unlimited colors.

- HTV requires cutting and weeding each design, making it time-consuming for complex graphics.

- DTF offers superior durability, resisting cracking and peeling better than HTV over time.

- DTF is more scalable for business growth, while HTV is better suited for hobbyists or small personalization projects.

For brand owners and business owners, HTV is a great entry-level option for small-scale, simple designs, but DTF provides greater efficiency and flexibility for larger operations. If you plan to expand your business with high-quality, professional-looking prints on a variety of fabrics, DTF is the better long-term investment.

Cost Comparison: Small vs. Large Orders

| Printing Method | Best for Small Orders? | Best for Large Orders? | Initial Investment | Cost per Print |

|---|---|---|---|---|

| DTF Printing | ✅ Yes | ✅ Yes | Moderate | Low-Medium |

| Screen Printing | ❌ No | ✅ Yes | High | Low (for bulk) |

| Sublimation | ✅ Yes | ✅ Yes | Moderate | Low |

| HTV | ✅ Yes | ❌ No | Low | High |

FAQs About Switching to DTF

Not necessarily! For small and medium orders, DTF is often more affordable because it doesn’t require costly screen setup.

Yes! Unlike sublimation, DTF works perfectly on both light and dark fabrics.

When properly applied, DTF prints are highly durable, lasting over 40 washes without fading or cracking.

You’ll need a DTF printer, PET films, hot-melt powder, and a heat press.

DTF transfers can be used on a wide range of fabrics, including cotton, polyester, nylon, and leather, but may not be suitable for very heat-sensitive materials. The versatility of DTF transfers makes them an excellent choice for a wide range of projects.

Each printing method has its strengths and weaknesses, but if you’re looking for a versatile, high-quality, and cost-effective solution, DTF printing is an excellent choice. Whether you’re a small business or an established print shop, DTF offers a flexible alternative to screen printing, sublimation, and HTV, making it a game-changer in the custom apparel industry.

Start Your DTF Journey Today

In today’s dynamic printing landscape, DTF (Direct to Film) printing emerges as a revolutionary technology poised to transform the way we create vibrant and detailed prints. From its seamless process to its exceptional print quality and versatility, DTF printing offers a multitude of benefits for businesses, entrepreneurs, and creatives alike.

At Hollywood Prints, we’re proud to offer a comprehensive range of custom DTF transfers that empower you to unleash your creativity and bring your designs to life with unparalleled precision and vibrancy. Our DTF transfers combine cutting-edge technology with superior materials to deliver prints that exceed expectations, whether you’re producing custom apparel, promotional items, or signage.

In conclusion, if you’re ready to elevate your printing projects to new heights, we invite you to experience the power of DTF printing with Hollywood Prints. Our custom DTF transfers offer unmatched quality, convenience, and versatility, enabling you to create stunning prints that captivate and inspire.

Order your custom DTF transfers from Hollywood Prints now and transform your designs!

Don’t settle for ordinary prints, improve your clothing today with DTF printing from Hollywood Prints!